Peter what impresses me the most is that you can make enough money over there to be able to do all of that!! Not trying to be a dick (it comes naturally) but I left in 91 and it was hard to keep just a ford transit tipper busy. Excellent job on all of it , how much weight imbalance will that turntable take??

I didn't answer the first part of your post earlier, not offended in any way but somewhat staggered by just how much of a downer you have on the UK. The forestry and arb industry contribute £2.1 billion to annual gdp. I need a tiny fraction of that to keep my tiny business going. Sure there's competition, yes you have to work hard for it, but there's work out there and the domestic sector where I do most of my work is unregulated. I haven't seen an HSE inspector on any site for 6 years, they have had so many cutbacks they can't leave the office. I could cut trees naked while swinging from some old polyprop and no one would give a shit.

I imagine in 91 the post 85 bubble had well and truly burst, and it was tough to compete with all the start ups, and everyone was a tree surgeon. I think what's changed since then is that everyone takes trees and safety a bit more seriously, I rarely get call out work, but we do a lot more surveys and preventative work.

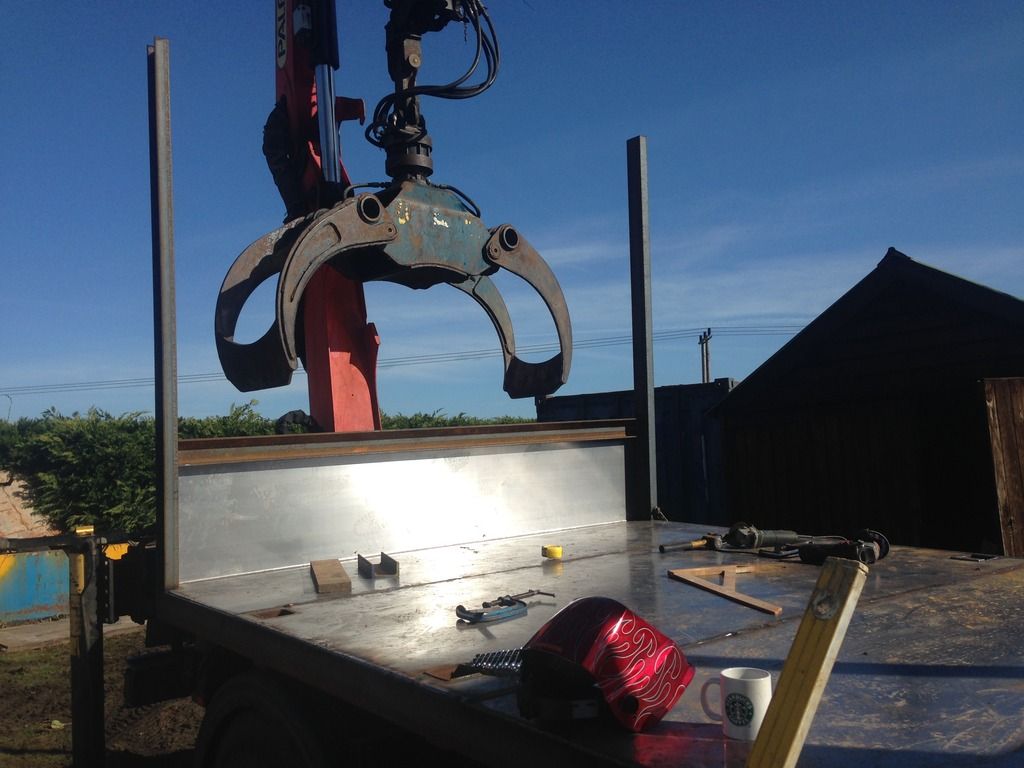

With regard to my machinery and trucks, I self build because I'm doing it on the cheap. The chipper cost me less than a third of the price of a new machine, the lorry I bought for £5k at the worst part of the recession. I had a quote from a body builder to do that tipping body, they wanted over £10k, I built it for about £1500.

But while I'm doing it on the cheap, there are plenty of guys buying brand new trucks and chippers. Trying to get a biomass chipper for a couple of days for a site clearance is almost impossible, everyone is flat out.

So it might not be utopia, but it's definitely possible to make a living.