- Thread Starter Thread Starter

- #51

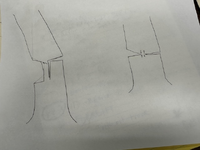

I think it contributes. The front compression half of a thick hinge could act as a fulcrum to pull the rear half tension fibers. I think it has more to do with whether the face closes before the hinge breaks or not. If the face closes, the log become a claw hammer pulling a nail (right drawing). It’s almost standard, automatic for a western cutter to trim the pull off the stump after felling, not necessarily just because it’s a Humboldt, but because they tend to end up deeper and more closed.Fiber pull has more to do with hinge thickness.

If the hinge bends until broken, it pulls down into the stump, instead of out of the log (left drawing). This is why eastern cutters make vertical hinge walls.

Back to the ‘chairing topic, the flare trim face and bore cut keep the whole rigid log together and eliminates fractures.

My bone to pick with eastern cutting is the short bars and the requisite dancing around the tree. All this boring and stuff is also tedious and I think simply not worth it for western timber.