combrig

TreeHouser

I really need help with that. This kind of equipment is not available on the market in my country, so I have to manufacture it myself. It is quite expensive, but compared to ordering the block from USA it is relatively cheaper.

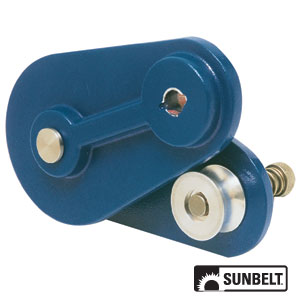

I decided to use stainless steel for the plates and the pins and aluminum alloy for the sheaves. I will use ball bearing for the bigger sheave and bronze or plastic bushing for the small sheave. One of the plates can be rotated (opened), while the other is fully static.

The problem, that I've encountered is with the spindle of the small sheave. It is important that the small sheave remains ON the block when the block is opened. Unfortunately, the pictures and YouTube videos didn't provide me any information on that how it can be done . I have a few ideas, but it's better to ask first so...

. I have a few ideas, but it's better to ask first so...

Can you make a pictures of the blocks that you are using and explain how exactly they are designed? I know, that maybe the design is licensed or something, but after all I don't intend to make hundreds of blocks... Just one.

Thank you!

P.S. Sorry if this thread isn't for this forum.

I decided to use stainless steel for the plates and the pins and aluminum alloy for the sheaves. I will use ball bearing for the bigger sheave and bronze or plastic bushing for the small sheave. One of the plates can be rotated (opened), while the other is fully static.

The problem, that I've encountered is with the spindle of the small sheave. It is important that the small sheave remains ON the block when the block is opened. Unfortunately, the pictures and YouTube videos didn't provide me any information on that how it can be done

. I have a few ideas, but it's better to ask first so...

. I have a few ideas, but it's better to ask first so...Can you make a pictures of the blocks that you are using and explain how exactly they are designed? I know, that maybe the design is licensed or something, but after all I don't intend to make hundreds of blocks... Just one.

Thank you!

P.S. Sorry if this thread isn't for this forum.