NickfromWI

King of Splices

I am looking to have an anchor welded that could be bolted to the floor. I would use this to anchor my splices when running them home. What I have in mind is something like the picture below.

I have a guy I found on craigslist that works by the hour ($25/hr). I'm guessing that's cheap and he's probably not a super experienced welder. But this seems like a basic project that might be well within his skill level.

My intention is to bolt this thing to a concrete floor.

I was thinking to use 3" square pipe because I saw that at a hardware store recently. There might be something better to use.

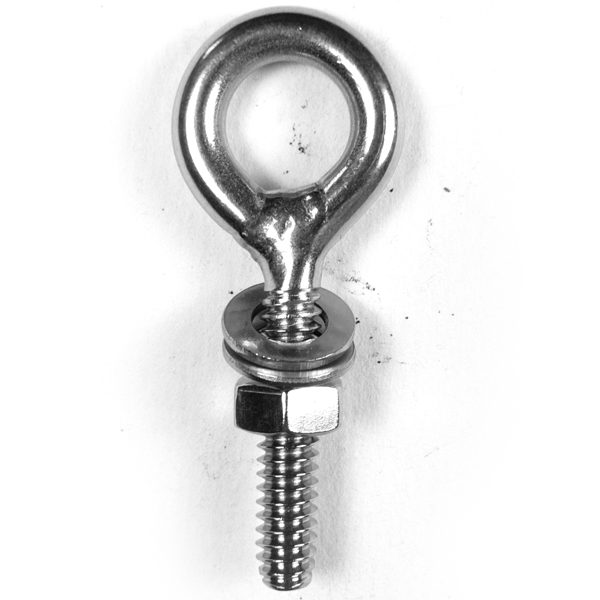

I intend to have something like this welded to the top:

Questions I have for you guys:

Can a welder weld a stainless hook to a "regular" metal? (can you tell I don't know about metal?)

What material would you make this out of?

How thick would you make the base plate? I'm thinking 1/4"

How long should it take this guy to make this thing?

How thick of a wall should I look for in the piping?

What, specifically, would be an easy hooked attachment method at the top? Welding a hook, bolting down a hook, drilling a hole in the top to screw in a heavy eye-hook?

I'm having it painted by this guy

love

nick

I have a guy I found on craigslist that works by the hour ($25/hr). I'm guessing that's cheap and he's probably not a super experienced welder. But this seems like a basic project that might be well within his skill level.

My intention is to bolt this thing to a concrete floor.

I was thinking to use 3" square pipe because I saw that at a hardware store recently. There might be something better to use.

I intend to have something like this welded to the top:

Questions I have for you guys:

Can a welder weld a stainless hook to a "regular" metal? (can you tell I don't know about metal?)

What material would you make this out of?

How thick would you make the base plate? I'm thinking 1/4"

How long should it take this guy to make this thing?

How thick of a wall should I look for in the piping?

What, specifically, would be an easy hooked attachment method at the top? Welding a hook, bolting down a hook, drilling a hole in the top to screw in a heavy eye-hook?

I'm having it painted by this guy

love

nick

I kind of had to pictorially prove that point a while back to one of my Canadian buddies over the net . I brazed a 1" schedule 40 stainless tube inside a carbon steel socket fitting . Never underestimate the tenacity of old age .

I kind of had to pictorially prove that point a while back to one of my Canadian buddies over the net . I brazed a 1" schedule 40 stainless tube inside a carbon steel socket fitting . Never underestimate the tenacity of old age .